A New Focus on Battery Transportation Safety: The Importance of Packaging Clamping Force Testing?

Jan 29, 2026

A New Focus on Battery Transportation Safety: The Importance of Packaging Clamping Force Testing?

With the growth of the new energy industry, various battery products such as lithium batteries and storage batteries have deeply penetrated multiple fields including new energy vehicles, energy storage, consumer electronics, and medical devices. Correspondingly, the demand for battery transportation has also shown exponential growth. However, as a special category of dangerous goods, batteries have always attracted close attention regarding safety risks during transportation. In addition to traditional risks such as high temperature, collision, and short circuit, safety accidents caused by the packaging clamping process have been increasing year by year, becoming a new focus in the field of battery transportation safety.

Real Risks Faced by Battery Packaging During Loading and Unloading

In the entire battery transportation process, clamping operations are a high-frequency stage for packaging damage. Scenarios such as forklift loading and unloading in ports and warehouses, and cargo stacking, all require the packaging to withstand squeezing forces from both sides. Once the load-bearing capacity fails to meet requirements, a series of risks may be triggered:

The packaging structure is compressed and deformed, causing uneven stress on the internal battery modules

Insufficient box strength leads to irreversible damage that is not easy to detect

Hidden safety hazards that may erupt collectively during subsequent transportation or use stages

This is precisely why more and more enterprises are beginning to attach importance to packaging clamping force testing.

What Is Packaging Clamping Force Testing?

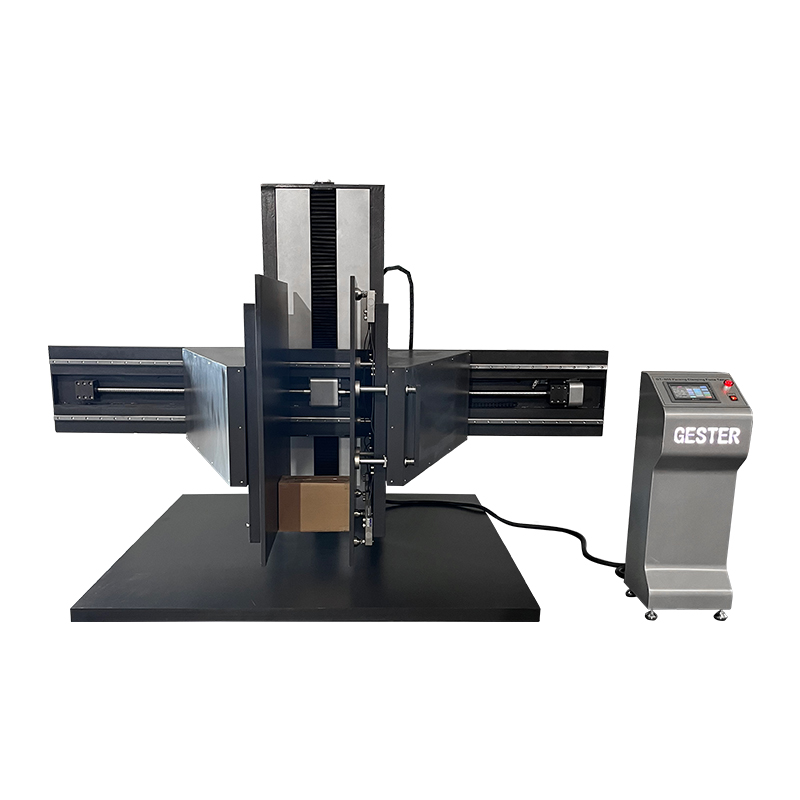

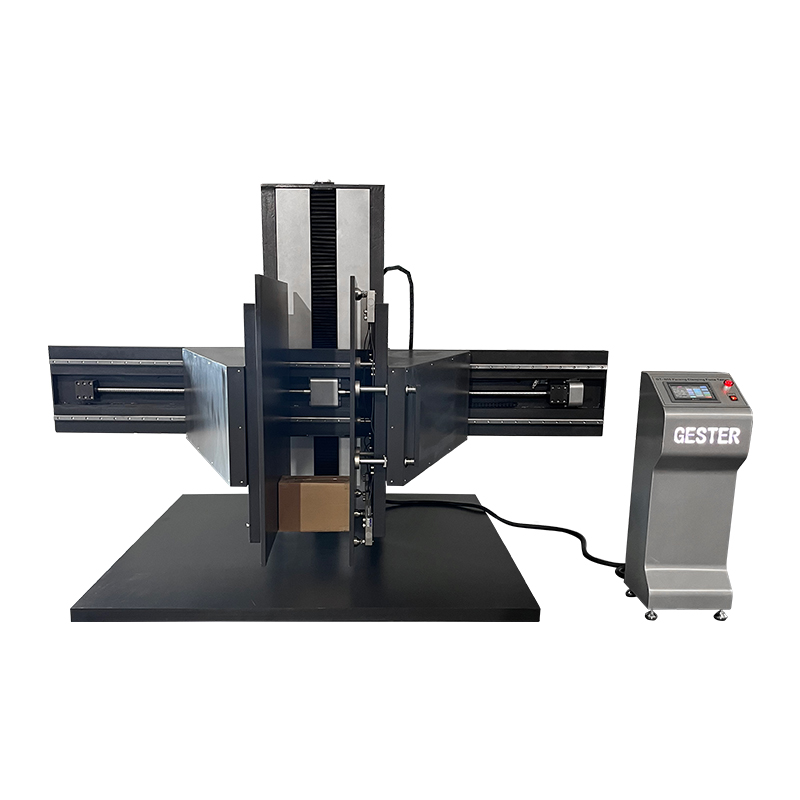

Packaging Clamp Force Lab Testing Machine is used for simulation when the clamp vehicle loading and unloading the package, the clamping force between two plywood impact on the package and goods, test and evaluate package’s clamp strength.

Why Must Battery Transportation Conduct Clamping Force Testing?

Verify the clamping load-bearing capacity of the packaging: Determine the maximum clamping force that the packaging can withstand during normal clamping operations, ensuring that the packaging will not be damaged or deformed due to excessive clamping force.

Identify defects in packaging design: Through testing, discover defects in structural design, material selection, cushioning protection, and other aspects of the packaging, such as insufficient material strength, unreasonable layout of cushioning materials, or improper design of clamping stress points, providing data support for packaging optimization.

Ensure battery transportation safety: Through pre-testing, ensure that the packaging can effectively protect the internal batteries and prevent accidents such as short circuits, leakage, or fires caused by clamping damage.

Meet compliance requirements: Through testing and obtaining qualified reports, ensure that the company’s battery packaging complies with relevant domestic and international regulations and standards, avoiding penalties due to non-compliance and ensuring smooth transportation and market access of products.

Reduce enterprise operational risks: Identify safety hazards in the clamping process in advance, reduce costs caused by cargo damage, accident compensation, and compliance penalties due to packaging damage, and enhance the stability of enterprise operations.

The Importance of Applications of Packaging Clamping Force Testing Machines

Professional Packaging Clamping Force Testing Machines are the prerequisite for the effectiveness of clamping force testing. If enterprises use testing equipment with insufficient accuracy or unrealistic simulation of working conditions, they will not only fail to obtain accurate test data, but may also mislead packaging design and compliance judgments, resulting in unqualified packaging entering the market and causing safety accidents and compliance risks. The application of high-quality testing equipment such as those from GESTER Packaging Clamping Force Testing Machine can ensure the accuracy and reliability of test results, provide strong support for enterprise compliance operations and packaging optimization, and further highlight the professionalism and importance of clamping force testing.

With the continuous development of the new energy industry, the scale of battery transportation will continue to expand, and the importance of transportation safety will become increasingly prominent. As a core measure to prevent safety risks in the clamping stage of battery transportation, packaging clamping force testing is not only a prerequisite for enterprise compliance operations, but also a key measure to safeguard personnel life safety and ecological environment safety, reduce enterprise operational risks, and enhance core competitiveness.