Everything You Need to Know About Sponge Resilience Tester GT-LE02

Jul 09, 2025

Everything You Need to Know About Sponge Resilience Tester GT-LE02

It is a cost-effective instrument designed for professional measurement of sponges, foam, rubber and other soft materials. The steel ball is mainly dropped freely on the sample of soft foamed plastic or other elastic materials. The Foam Resilience Tester for measuring its rebound height is mainly used to determine the rebound performance (rebound coefficient) in the testing items of polyurethane elastic materials.

Main Application Scope and Functions

This Foam Resilience Tester is suitable for determining the falling ball resilience of soft polyurethane foams. The Sponge Resilience Tester through the given diameter and quality of the steel ball in the specified height of the free fall on the foam sample, calculate the maximum height of the steel ball rebound and steel ball fall height ratio of the percentage of the rebound rate, the rebound rate represents the resilience of the foam. The Foam Material Drop Ball Rebound Resilience Tester adopts microprocessor control, touch screen Chinese display, and can print test data. This machine has the characteristics of safety, reliability and high measuring accuracy.

Working Principle

Put a square sample on the lower platform, and Repeatedly recess the sample by an indenter, whose size is smaller than the specimen. Reach the max.load under a certain range during each impact period, and then evaluate the sample performance after a certain times.

Standards:

GB/T 18941, GB/T 12825, ISO 3385, ASTM D3574-TEST I3

How to Conduct the Sponge Resilience Tester

1. Acceptance

-

Accessory display: Steel ball, magnetic rod

-

Put the instrument on the platform and adjust the feet according to the level bubble to make the instrument level.

-

Connect the power and turn on the power switch.

2. Operation

-

Prepare a 100 mm x 100 mm x 50 mm specimen (Note: If the thickness is insufficient, the stacking method can be used).

-

Put the sample into the specimen holder.

-

Turn on the emergency stop switch.

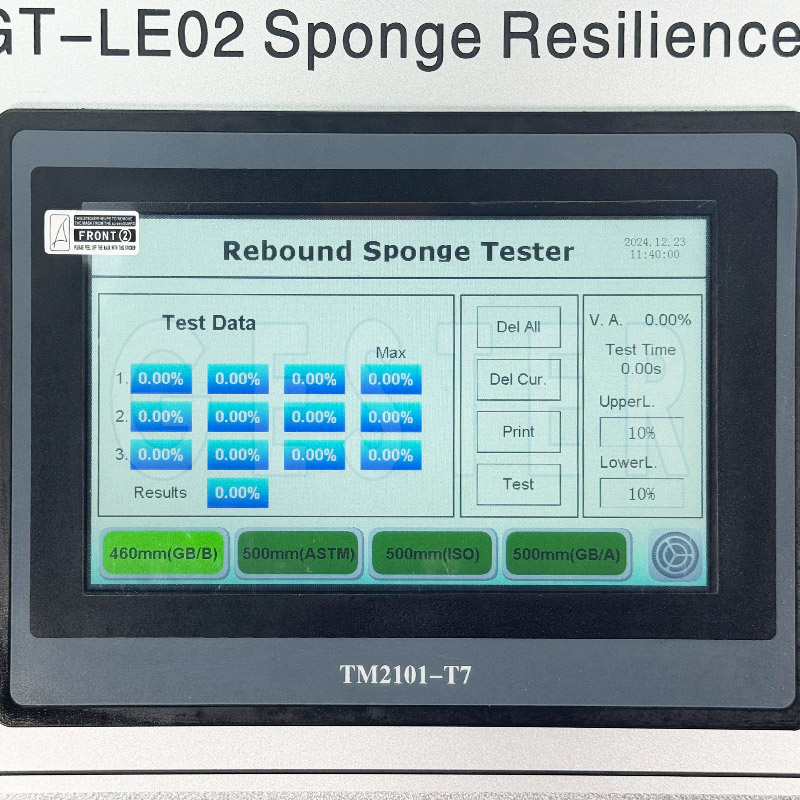

3. Enter the main interface.

-

Click “Del All” to clear all data, click “Del Cur.” to clear current data.

-

“UpperL./LowerL.” deviation setting: Can be set according to your needs.

-

Click to select “460mm” or “500mm” as desired.

-

If choose 460mm, please adjust the plexiglass tube to 460mm position.

-

If choose 500mm, please adjust the plexiglass tube to 500mm position.

-

Turn the mechanical magnet to ON and install the steel ball.

-

Click the “Test” button, turn the mechanical magnet to OFF position, the steel ball falls freely, completes a test, and displays the test result value.

4. Result

-

Use the magnetic rod to draw steel ball out, and reinstall it to test again.

-

Each group should be tested three times and completed within 60S. After completing all tests, click “Print” to print the results.