Chair Seating and Back Testing Machine: An Insight into Applications and Features

Dec 12, 2024

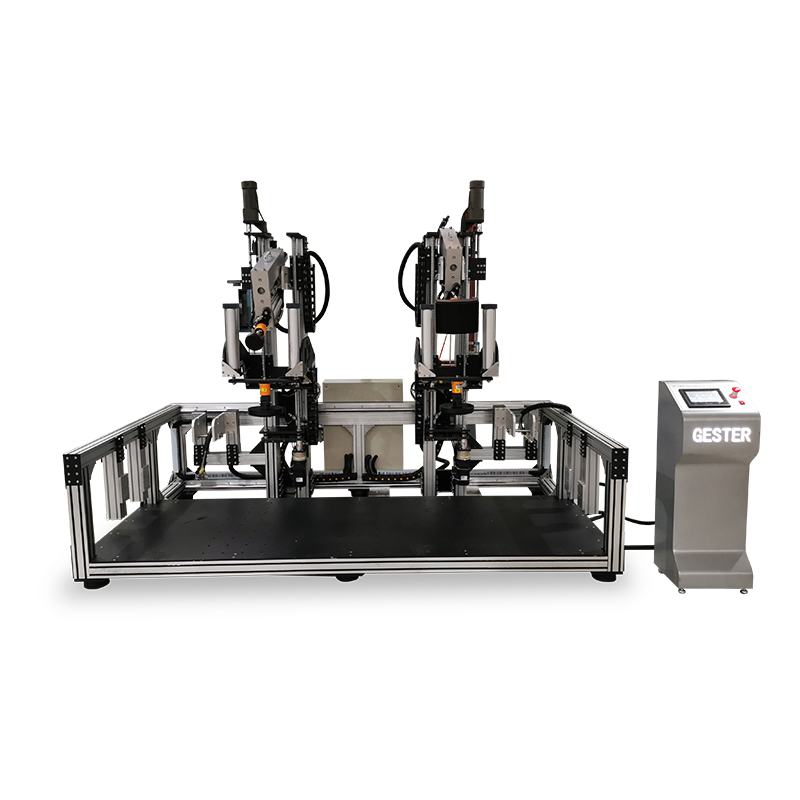

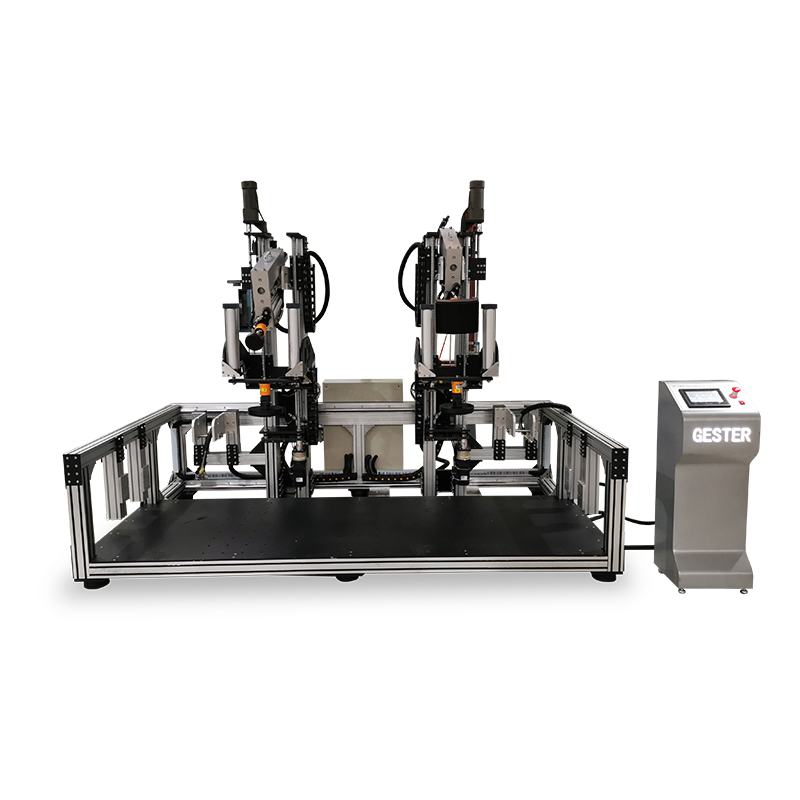

Chair Seating and Back Testing Machine:

An Insight into Applications and Features

In the modern furniture industry, quality assurance plays a critical role in maintaining customer satisfaction and meeting rigorous industry standards. Among the essential tools for furniture testing is the Chair Seating and Back Testing Machine, a sophisticated device designed to evaluate the strength and durability of chair seats and backrests under simulated daily usage conditions.

This article delves into the machine's applications, key features, and the benefits it offers to manufacturers striving for excellence in product quality.

Applications of Chair Seating and Back Testing Machine

The Chair Seating and Back Testing Machine serves as a comprehensive solution for testing various aspects of chairs, ensuring they can withstand prolonged use and maintain structural integrity. Here are the primary applications:

1. Seat and Back Static Load Test

This test evaluates the strength of a chair’s seat and backrest under consistent pressure. It ensures that the chair can bear weight without compromising its structural integrity.

2. Seat and Back Durability Test

Simulating repetitive loading conditions, this test assesses how well a chair can endure regular use over time, identifying potential wear points.

3. Seat Front Edge Static Load and Durability Test

The front edge of a chair is often subjected to concentrated stress. This test ensures the edge can resist deformation and maintain comfort for users.

4. Horizontal Forward Static Loading Test for Backrest

This test applies forward pressure on the backrest, mimicking the force exerted by users as they lean back, ensuring stability and safety.

5. Headrest Static Load Test

For chairs with headrests, this test determines whether the headrest can support pressure without bending or breaking.

6. Legs Forward and Lateral Static Load Tests

The legs of a chair are critical for stability. These tests evaluate their ability to withstand forces from different directions, ensuring the chair remains stable on various surfaces.

7. Impact Tests with GT-LB01-7 Impact Hammer (Optional)

When equipped with the GT-LB01-7 Impact Hammer, the machine can perform:

Backrest Impact Test: Simulating sudden impacts to the backrest to assess its durability.

Armrest Impact Test: Testing the strength of the armrests under repeated impacts.

Key Features of the Chair Seating and Back Testing Machine

1. Dual Working Positions

The machine features two independent drive devices, allowing simultaneous testing on multiple points. This design enhances testing efficiency, reducing overall testing time.

2. Aluminum Main Structure

The machine's aluminum construction provides a sleek appearance, durability, and easy maintenance, making it ideal for long-term industrial use.

3. Servo Proportional Valve and Air Cylinder Drive

This advanced technology ensures precise loading controls, offering accurate and consistent test results while minimizing operational noise.

4. PLC Touch Screen Control

A user-friendly PLC touch screen simplifies test setup and operation. Users can easily adjust parameters for different tests, ensuring flexibility and convenience.

5. Electric Control Movements

The electrically controlled loading device accommodates chairs of various sizes, providing flexibility for different testing requirements.

Benefits of the Chair Seating and Back Testing Machine

1. Improved Product Quality

By thoroughly testing each component of a chair, manufacturers can ensure their products meet or exceed industry standards, resulting in higher customer satisfaction.

2. Enhanced Efficiency

The dual working positions and automated control systems streamline the testing process, saving time and labor costs.

3. Precision and Reliability

The combination of servo proportional valve technology and PLC controls ensures tests are performed with unmatched accuracy, delivering reliable results.

4. Customization Capabilities

The optional impact testing functionality allows manufacturers to tailor the testing process to their specific product designs, ensuring comprehensive evaluations.

5. Cost-Effectiveness

By identifying potential weaknesses during testing, manufacturers can make necessary adjustments before mass production, reducing warranty claims and product returns.

Why Choose the Chair Seating and Back Testing Machine?

Chair Seating and Back Testing Machine is not just a testing device—it is a pivotal part of quality assurance for chair manufacturers. Here’s why it stands out:

-

Versatility: It covers a broad range of tests, from static load to durability and impact assessments.

-

Advanced Technology: Features like servo proportional valves and PLC controls set it apart from conventional testing machines.

-

Durability: Built with high-quality materials, the machine ensures long-term reliability, even under heavy industrial use.

-

Flexibility: With the optional impact hammer and adjustable settings, it caters to a variety of chair designs and testing requirements.

Conclusion

The Chair Seating and Back Testing Machine is an invaluable tool for furniture manufacturers committed to delivering durable and high-quality chairs. Its advanced features, extensive testing capabilities, and user-friendly design make it a reliable partner in quality assurance.

Investing in this machine means investing in customer satisfaction and brand reputation. Ensure your chairs meet the demands of modern consumers with precision-driven testing processes provided by the Chair Seating and Back Testing Machine.

For more details on how this machine can elevate your manufacturing processes, reach out to our team today!