What is 100KN Carton Box Compression Tester

Apr,26 2023

The 100KN Carton Box Compression Tester is a device used to measure the compressive strength of a carton box or other packaging materials. The machine applies pressure to the top of the box or material to simulate the weight that it would experience during transportation or storage. The pressure is increased gradually until the box or material collapses, and the maximum amount of pressure that it can withstand before collapsing is recorded.

The Basics of Box Compression Testing

To perform a box compression testing, a sample box is placed on a flat surface and a compressive force is applied from the top. The force is gradually increased until the box collapses or reaches a predetermined limit. The amount of force required to crush the box is measured in pounds or kilograms, and this value is used to calculate the box's compression strength.

Why Accurate Results are Important

A company that produces fragile electronic components. These components need to be packaged carefully to avoid damage during shipping. The company uses boxes made from a certain type of cardboard that they believe is strong enough to protect the components.

However, the company does not perform regular compression test for corrugated boxes to ensure the strength of the boxes. As a result, some of the components are damaged during shipping, leading to customer complaints, returns, and lost revenue.

Upon investigating the issue, the company discovers that the cardboard boxes they are using have a lower compression strength than they initially thought. If they had performed regular box compression tests, they would have known this and could have chosen a stronger material for their boxes.

In this example, accurate box compression test results could have helped the company avoid costly issues such as customer complaints and returns, as well as identify the need for a stronger packaging material to better protect their products during shipping.

Accurate box compression test results are critical for several reasons. First and foremost, they provide valuable information about the quality and strength of the packaging material being used. Inaccurate test results can lead to products that fail to meet industry standards or that are prone to damage during shipping. This can result in customer complaints, returns, and even legal issues if products are damaged during transit.

By analyzing the test results, manufacturers can identify weaknesses in their packaging materials and make adjustments to improve their strength and durability. This can lead to cost savings in the long run, as well as improved customer satisfaction and loyalty.

Factors That Affect Test Results

Several factors can affect the accuracy of box compression test results. These include the type of box being tested, the testing method used, and the condition of the testing equipment. To ensure accurate results, it's essential to follow industry-standard testing procedures and use well-maintained and calibrated equipment.

1. Compression speed: The speed at which the box is compressed can impact the test results. If the compression speed is too fast, it can cause inaccurate readings due to the box's viscoelastic behavior.

2. Temperature and humidity: The temperature and humidity of the testing environment can affect the material's properties and, consequently, the test results. Higher temperatures and humidity levels can cause the material to become softer, leading to lower compression strength.

3. Box size and design: The size and design of the box being tested can impact the results. A larger box may require a higher compression force to reach its breaking point, while a smaller box may break at a lower force. Similarly, a box's design, such as the presence of flaps or reinforcements, can affect its compression strength.

4. Edge effects: The edges of the box being tested can be more prone to failure due to manufacturing defects or stress concentration. Edge effects can lead to inconsistent results, making it essential to ensure that the box's edges are in good condition and uniform.

5. Equipment calibration: The accuracy of the test results depends on the equipment used to conduct the test. It's crucial to ensure that the equipment is calibrated correctly, and any potential errors or malfunctions are addressed before conducting the test.

6. Sample size: The sample size of the boxes being tested can affect the results. Testing a larger sample size can provide a more representative picture of the material's compression strength.

Choosing the Right Box Compression Tester

Choosing the right box compression tester is also crucial for accurate results.

When choosing a box compression tester, it's essential to consider factors such as the size and weight of the boxes being tested, the testing volume, and the level of automation required. It's also important to choose a tester from a reputable manufacturer that offers excellent customer support and service.

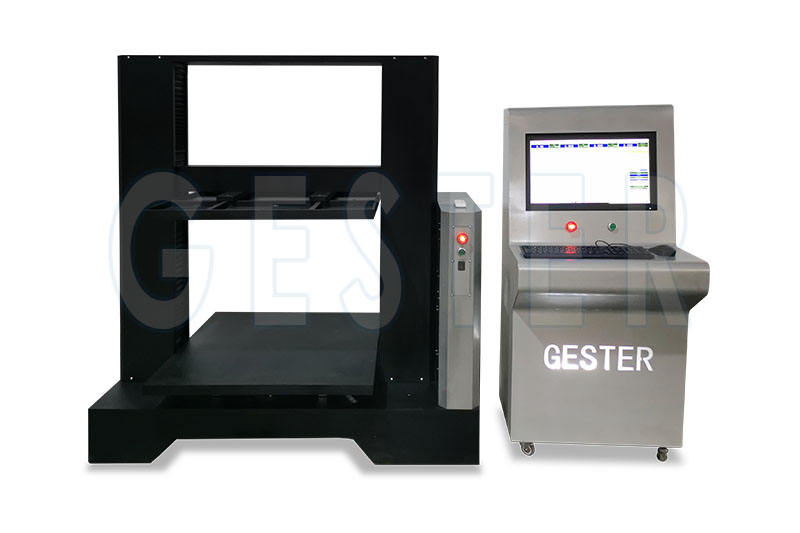

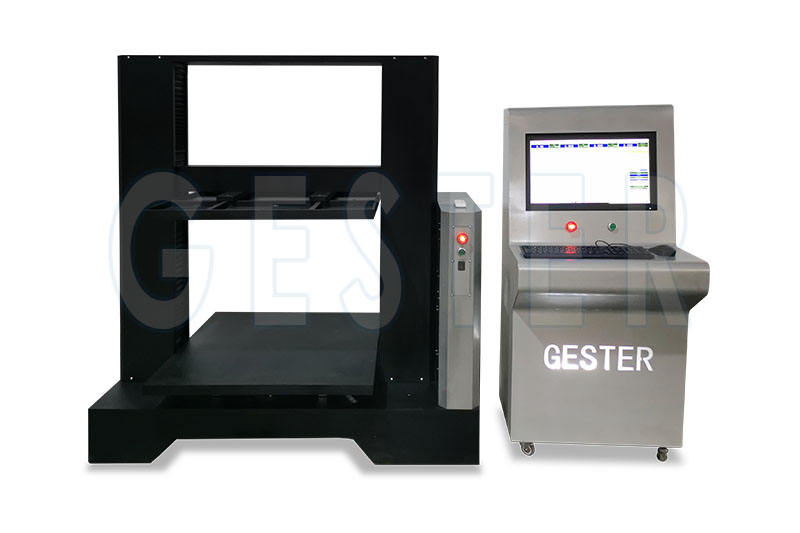

100KN Carton Box Compression Tester GT-N02D uses high-precision force sensor to test the resistance value of pressure and display it directly. The most direct equipment for testing the pressure resistance of containers made of cardboard or other materials. It is used to determine the cargo capacity and stacking height of the carton. It is suitable for the compression and holding test of various packages and cartons. The test results can be used as an important reference for the stacking height of the finished packaging box or an important basis for packaging box designing.

Corrugated Box Compression Strength Tester with multi-function and high precision is designed to test the compressive strength of standard size corrugated box, or packages and containers made of other material with a compressive strength smaller than 100kN. With advanced mechanical structure of a pair of threaded shafts &guide pillars and imported motor for control, the testing machine has the following salient features: good parallelism, reliable measure precision and high return speed.

The Carton Box Compression Tester is an important tool for manufacturers, distributors, and retailers who need to ensure that their packaging materials can withstand the rigors of transportation and storage without damaging the contents inside. By testing the compressive strength of their packaging materials, they can make sure that their products arrive at their destination in good condition, which helps to reduce waste and save money.